Robotic technology has revolutionized the manufacturing industry. It has made it possible to automate many tasks that were once performed by humans, including the handling of plastic parts. However, handling plastic parts presents unique challenges due to their fragility and variability in shape and size. This is where grippers come into play. In this blog post, we will explore the role of grippers in the robotics industry for handling plastic parts.

Grippers are mechanical devices that are used to hold and manipulate objects. They come in a variety of shapes and sizes and are designed to work with different materials. Grippers for plastic parts are specifically designed to handle the fragile and often complex shapes of plastic components. They are essential in automating the manufacturing process and increasing efficiency.

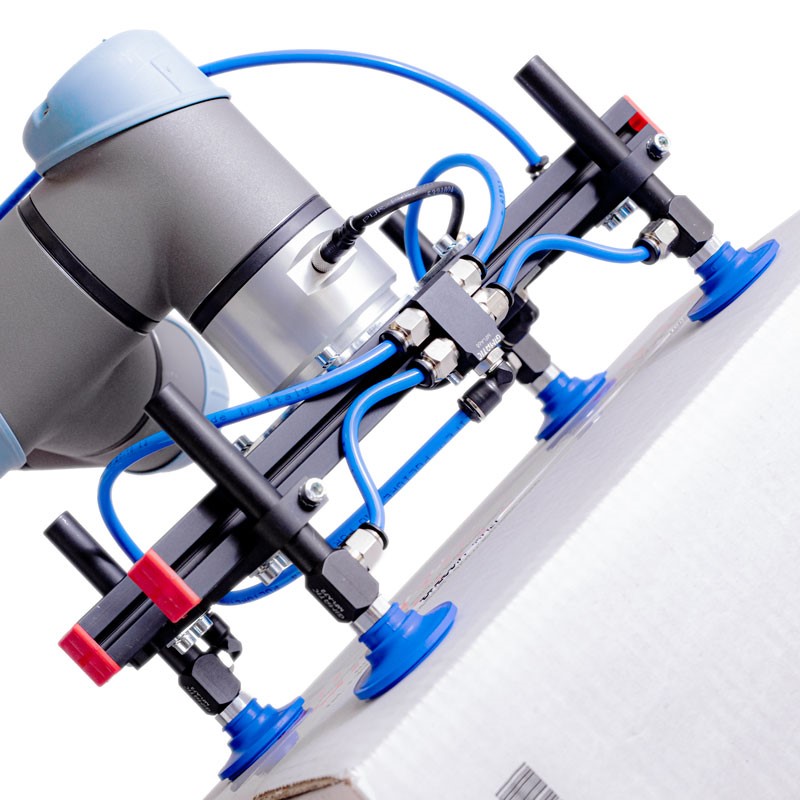

One of the challenges of handling plastic parts is that they are often very light and delicate, which makes them difficult to grip. To overcome this, grippers are designed with features such as suction cups, vacuum grippers, or soft, flexible fingers. These features enable the grippers to grip the plastic parts without causing any damage.

In addition to being delicate, plastic parts are often irregular in shape, making it challenging to design grippers that can handle them. To address this issue, grippers are designed with flexible fingers that can adapt to the shape of the part being handled. Some grippers are also designed to have interchangeable fingers, which makes it possible to handle different types of plastic parts with the same gripper.

The use of grippers in the robotics industry has increased efficiency and productivity in the manufacturing process. With the use of grippers, robots can handle plastic parts with speed and precision, reducing the likelihood of errors and defects. This results in cost savings and faster production times.

In conclusion, grippers play a crucial role in the robotics industry for handling plastic parts. They are designed to be delicate and flexible, making it possible to handle fragile and complex plastic components with speed and precision. The use of grippers in the manufacturing process has increased efficiency and productivity, resulting in cost savings and faster production times. As the demand for automation in the manufacturing industry continues to grow, the importance of grippers in the robotics industry will only continue to increase.